Maintaining a safe working environment and safeguarding employees from potential hazards is a top priority for any organization. While it may be impossible to completely eradicate accidents or injuries, businesses can significantly reduce risks by adopting effective control measures. One widely recognized and structured approach to achieving this is the Hierarchy of Controls. By embracing this framework, employers can systematically address workplace hazards and create a safer environment for their workforce. In this blog post, we will delve into the concept of the Hierarchy of Controls and explore its practical applications in promoting workplace safety.

Understanding the Hierarchy of Controls

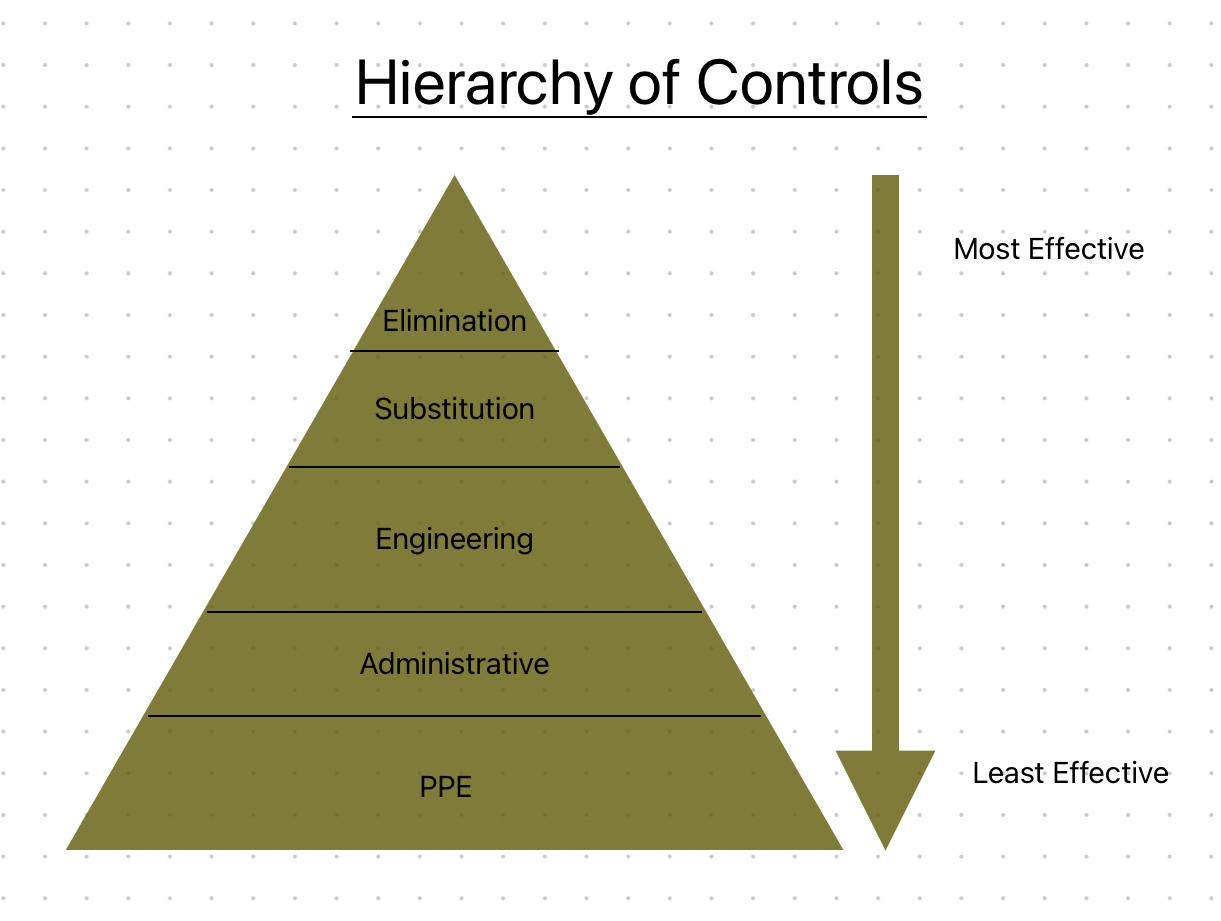

The Hierarchy of Controls is a risk management tool that offers a systematic framework for reducing or eliminating workplace hazards. It provides a prioritized list of control measures, ranked in order of effectiveness, to guide safety decision-making. The five levels of the hierarchy, in descending order of effectiveness, are elimination, substitution, engineering controls, administrative controls, and personal protective equipment (PPE).

Elimination

The most effective control measure is to eliminate the hazard altogether. By removing the hazard from the workplace, organizations can significantly reduce the associated risks. For example, if a hazardous chemical is no longer necessary for a particular process, replacing it with a safer alternative or using a different process altogether eliminates the need to handle the hazardous substance.

Additional Examples:

- Use a long handled paint roller to paint areas out of reach instead of using a ladder to gain access

- Replace a manually operated heavy lifting task with an automated lifting mechanism, removing the need for workers to physically handle heavy loads.

Substitution

If elimination is not feasible, substitution is the next best option. This involves replacing the hazardous material or process with a less dangerous alternative. For instance, substituting a toxic cleaning agent with an environmentally friendly and non-toxic alternative ensures a safer work environment for employees.

Additional Examples:

- Substitute a solvent-based paint with a water-based paint that emits fewer volatile organic compounds (VOCs) and poses fewer health risks to painters.

- Replace a noisy piece of machinery with a quieter alternative to reduce noise exposure for workers.

Engineering Controls

Engineering controls are physical modifications or systems implemented to isolate workers from hazards. These controls aim to minimize exposure to risks by altering the workplace environment. Examples include installing ventilation systems to control airborne contaminants, implementing machine guards to prevent contact with moving parts, or designing ergonomic workstations to reduce the risk of musculoskeletal disorders.

Administrative Controls

Administrative controls focus on changing work practices and procedures to reduce exposure to hazards. This level of control includes implementing policies, providing training and education, establishing standard operating procedures, and enforcing work schedules or rotation to minimize exposure time. Effective communication, signage, and warning systems are also crucial elements of administrative controls.

Additional Examples:

- Develop and implement a comprehensive safety training program to educate workers on proper handling of equipment, emergency procedures, and hazard recognition.

- Establish a policy requiring regular breaks for workers performing repetitive tasks to minimize the risk of musculoskeletal disorders.

Personal Protective Equipment (PPE)

When all other control measures have been exhausted, personal protective equipment (PPE) becomes the final line of defense. PPE includes items such as gloves, safety glasses, helmets, respirators, and protective clothing. While PPE does not eliminate hazards, it helps protect workers by providing a physical barrier between them and the hazards they encounter.

Additional Examples:

- Provide workers with safety goggles, gloves, and respirators to protect against chemical splashes, contact with hazardous materials, and respiratory hazards.

- Equip workers in construction sites with hard hats and steel-toed boots to safeguard against head injuries and foot-related hazards.

Applying the Hierarchy of Controls

Implementing the Hierarchy of Controls requires a systematic approach to hazard identification, assessment, and control selection. Here’s a step-by-step process to guide you:

- Identify Hazards: Conduct a comprehensive workplace hazard assessment to identify potential risks. This can involve observations, inspections, reviewing incident reports, and involving employees in the process.

- Assess Risks: Evaluate the likelihood and severity of each identified hazard. This assessment will help determine the priority level for implementing control measures.

- Select Controls: Utilize the Hierarchy of Controls to prioritize and select appropriate control measures for each hazard. Start with elimination and work your way down the hierarchy, considering feasibility, effectiveness, and cost.

- Implement Controls: Develop an action plan to implement the selected control measures. Ensure clear responsibilities, timelines, and resources are allocated for successful implementation.

- Monitor and Review: Regularly assess the effectiveness of implemented controls and make necessary adjustments. Monitor ongoing compliance, gather feedback from workers, and stay updated on emerging control technologies and best practices.

Final Thoughts on the Using the Hierarchy of Controls

Protecting workers from workplace hazards requires a proactive and systematic approach. The Hierarchy of Controls provides a roadmap for selecting the most effective control measures to minimize risks. By implementing the hierarchy, organizations can create safer work environments, reduce incidents, and foster a culture of safety. Remember, the ultimate goal is to eliminate or mitigate hazards at the source rather than relying solely on personal protective equipment. Let us embrace the power of the Hierarchy of Controls and build a safer future for all workers.